When it comes to durability and aesthetics, there’s no match for natural stone; every piece is unique, with a huge range of stunning colours and textures determined by millennia of geological processes. And it’s so strong it will outlast us all, making it a sound investment.

There are many different types of natural stones commonly used for paving projects such as; sandstone, limestone, granite, basalt and slate from countries such as India, China, Vietnam, Brazil, Egypt, Morocco, Turkey and Portugal to name just a few.

So if you’re choosing natural stone for your garden, how do you decide on the right product? You’ll need to think about its position, appearance, colour and the finish.

The processes and finishing applied to a stone can mean that a completely different look and effect can be achieved using exactly the same type of stone. Some finishes are better suited to certain types of stone.

How the finish can change the look

- In the example below, Fossil Mint Indian Sandstone which is an extremely popular option for paving is finished in several different ways. The most common and cost effective is the natural finish, the tumbled antique finish gives a softer, time-worn look whilst the honed and sandblasted finishes create a more modern look and a completely flat surface, with the sandblasting providing greater grip. When stone such as this is honed or sandblasted many of the markings (which some may view as blemishes) in natural stone tend to disappear and a more even colour tone is achieved.

2. This next example illustrates how different Asian Blue (Vietnamese) Limestone can look depending on the finish applied. The finishes are clockwise from top-left; honed & tumbled, honed, tumbled, flamed & brushed, bush-hammered.

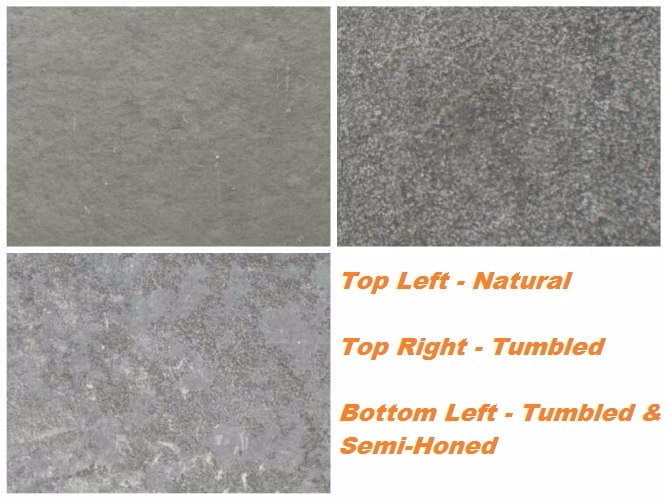

3. This example shows three different finishes for Tandur Grey Indian Limestone.

Stone Finishes Explained

- Natural (Cleft) – This natural surface results when stones like sandstone and slate are quarried and split. The type of stone depends how heavily riven the surface will be.

- Antiqued/Tumbled – The stone is distressed by vibrating it in a container/mixer of sand and grit (and sometimes acid). The result is a finish that looks aged and worn.

- Sawn – The natural stone is sawn and without any other processes such as honing, tumbling or flaming, the saw marks are likely to be visible.

- Polished – A smooth and reflective surface that is generally reserved for indoor areas such as hotel receptions, table-tops etc. due to it being less slip resistant. Increasingly finer abrasives are used and the stone is buffed to a high gloss which really brings out the colour of the stone.

- Honed – The stone is grinded and sanded using coarse grit abrasives to create a smooth but satin, non-reflective finish.

- Flamed – A rough textured finish results as the stone is torched with a flame which causes a thermal shock and fractures the crystals within the stone. This is a popular way of finishing natural granite paving.

- Brushed – Steel or hard nylon brushes are used along with water to brush and wear out softer parts of the stone. This creates a textured finish and an antique look.

- Sandblasted – A textured surface is created as sand is blasted at high pressure. Shot-blasting is a similar process. The process often lightens the stone as well as masking the character by hiding the veins and fossils within the stone.

- Bush-Hammered – A high anti-slip finish can be created using this technique where a bush hammer is applied by machine or hand at high impact to pit the surface of the stone, as per the example on the Asian Blue Limestone above.

- Chiselled – Lines are mechanically chiselled into the stone to create an anti-slip finish.

Edges

The edges of paving slabs may be hand cut which gives a more traditional look whilst machine sawn edges can lend themselves to a clean contemporary look. In a garden landscaping environment the edges of paving stones maybe bull-nosed or rounded for steps or pool surrounds or profiled in some other way for copings and pier caps.

The post Natural Stone Paving Finishes appeared first on Kebur.